When it comes to manufacturing a wire harness, there are a few key factors you need to take into account. The design of the wire harness will have a significant impact on its performance and overall efficiency. This blog post will discuss some of the most important factors to consider when designing a wire harness. By following these tips, you can create a wire harness that is both reliable and cost-effective. If you need help with this process, Allplant auto electrics in Western Australia has the expertise to deliver superior quality wiring solutions every time.

One of the most important considerations when designing a wire harness is the environment in which it will be used. The type of environment will determine what materials should be used and how the components need to be protected from harsh weather conditions or other external factors. Make sure to consider things like temperature, humidity, and any other environmental dangers that could potentially damage the components of the wire harness.

Examine Material Durability

Durability is also a key factor when designing a wire harness. The materials used need to be able to withstand any wear and tear over long periods. This means selecting high-quality components designed for long life and reliable performance. It’s also important to consider any possible environmental vibrations or shocks, as these can also lead to damage.

Consider Flexibility

Flexibility is another key factor when designing a wire harness. The structure needs to bend and twist without causing any damage or impact on performance. To achieve this, it’s important to use components designed specifically for flexibility and movement. In addition, the design should also withstand any changes in the environment or external factors that might cause stress on the wires.

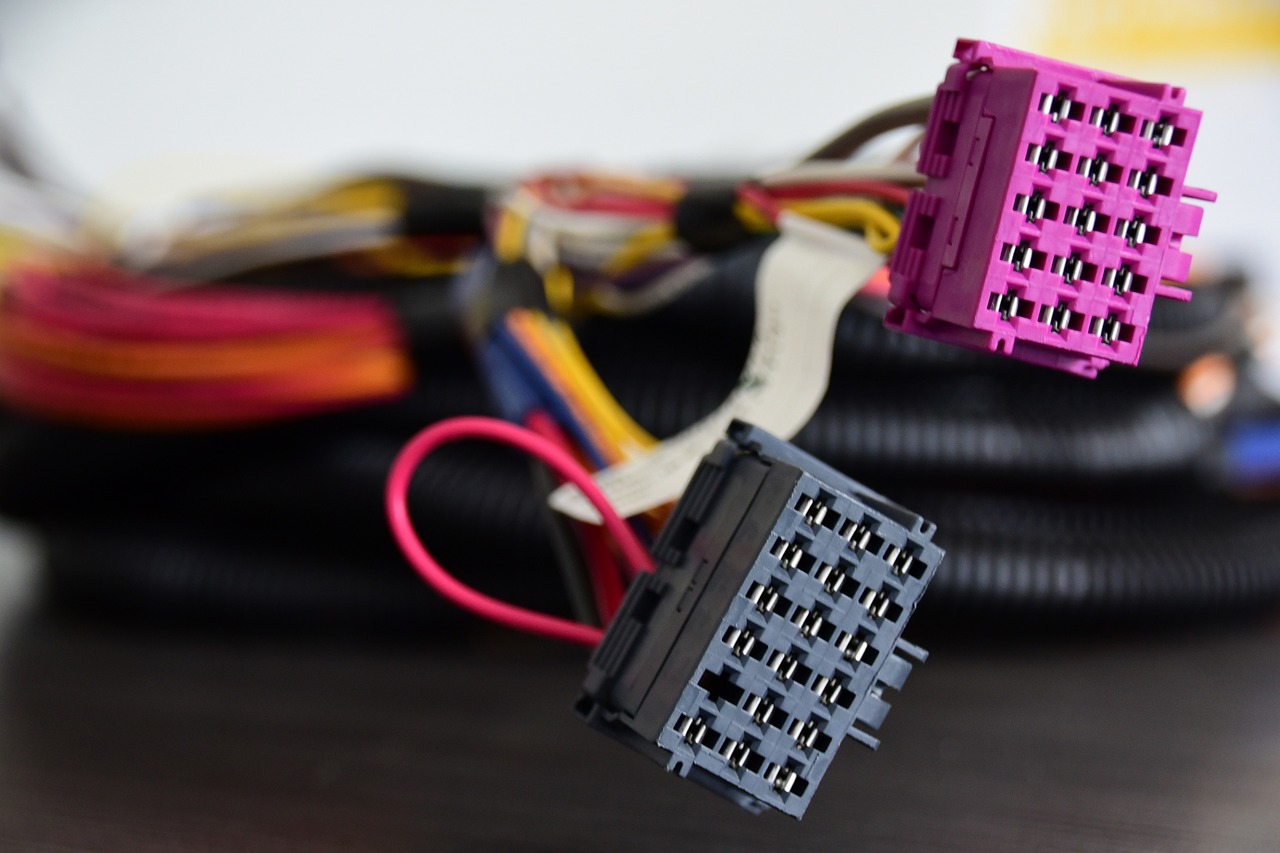

Ease of Assembly

Finally, it would help if you considered the ease with which the wire harness can be assembled. This will largely depend on how complicated the design is, so make sure the components used are easy to fit together without requiring extra steps or complex techniques. Additionally, it’s important to use compatible components, as this will make the assembly process much smoother and less time-consuming. Considering all of these factors when designing a wire harness, you can ensure that your final product is reliable and cost-effective. With the right design in place, you can rest assured knowing that your wire harness will be up to the task and ready for any environmental conditions or external factors it may encounter.